ACCESS - HAVAİ İŞ PLATFORMU KONTROL SİSTEMİ

Ürün Markası: PG Sürücü Teknolojisi

DÜŞÜK GERİLİM MOTOR SÜRÜCÜLERİ:

Geniş yelpazeli Motor sürücüleri, AC motor kontrolü, kalıcı mıknatıslı DC motor kontrolü ve transpaletler, istifleyiciler, çekiciler, forkliftler veya diğer tipte Akü ile çalışan araçlar gibi çok çeşitli elektrikli araçlar için uygun olan birbirinden bağımsız tahrikli motor kontrolü sunar.

Tüm ürünler, kompakt ve sağlam tasarım, performans, performans, işlevsellik ve maliyetin mükemmel bir kombinasyonudur.

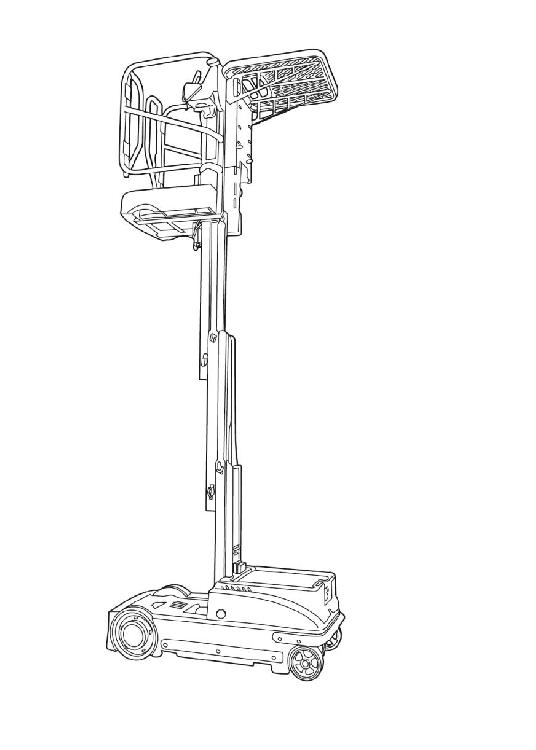

"Access" çekiş, yön ve kaldırma / indirme hızları dahil, Havai Çalışma Platformlarının tüm işlevselliğini kontrol etmek için entegre bir sistemdir.

- Kanal başına çift 120A çekiş motoru sürücüsü

- Platform kontrol arayüz paneli

- Çekiş ve direksiyonun orantılı kontrolü

- 150 A pompa motor çıkışı

- Kaldırma ve alçaltmanın orantılı kontrolü

- Geniş, okunması kolay arkadan aydınlatmalı LCD ekran

- Dahili eğim sensörü

- Alarm, uyarı ışığı ve korna çıkışları

- Yerleşik programlama

"Access" değişken kaldırma, indirme ve çekiş dahil olmak üzere havai çalışma platformlarının tüm işlevselliğini kontrol etmek için entegre bir havadan çalışma kontrol sistemidir. Sistemin üç modülü, makine kapasitesini artırmak ve kurulum hatalarını azaltmak için basit ve kolay bir şekilde bağlanır.

Geçiş Kontrol Sistemi aşağıdaki üç modülden oluşur:

Joystick Arayüz Modülü (JIM)

Arayüz Modülü, tüm platform kontrol kullanıcı anahtarları ve kumanda kolu için uygun bağlantı noktaları sağlar. Elektronik parçalar, maksimum çevre koruması için "gömülüdür" ve entegre conta, modülün takıldığı panelin tamamen su geçirmez kalmasını sağlar.

Çekiş Modülü

Çekiş Modülü, sabit mıknatıslı motorlar için iki adet 120A değişken hız çıkışına ve ayrıca elektromanyetik frenler için iki bağlantılı çıkışa sahiptir. Modül, basit ve sorunsuz kablolama için Zemin Kontrol Modülüne bir seri bağlantı aracılığıyla bağlanır.

Zemin Modülü

Bu, kablo demetini basitleştirerek bağlantı sisteminin merkezini oluşturur. Bu modül doğrudan sistem akülerine bağlanır ve hidrolik pompa motoru için yüksek akım değişken hız çıkışını temin etmenin yanı sıra değişken down valf, alarm, korna ve uyarı ışığı gibi daha düşük akım çıkışlarını temin eder. Çukur/limit anahtarları, yükseltme veya yardımcı girişler için tüm giriş anahtarı kablo demetleri, harici parçaların servisini kolaylaştırmak için buraya bağlanır.

Yer Modülü, servis mühendislerinin ve OEM'lerin ek el veya PC programlama araçlarına ihtiyaç duymadan üç sistem modülü için parametreleri ayarlamasına ve bilgileri görüntülemesine olanak tanıyan Yerleşik Programlama (OBP) özelliğine sahiptir. OBP'ye, başlatma sırasında bir tuşa basma dizisi aracılığıyla erişilir, izin verilen erişim seviyesi, girilen şifre sırası ile belirlenir ve her OEM'in gereksinimleri için özelleştirilebilir. Servis mühendisi şifresinin girilmesi, yalnızca sınırlı sayıda fonksiyonun düzenlenmesine izin verirken, OEM şifresi tüm sistem parametrelerinin düzenlenmesine izin verir.

Geniş, arkadan aydınlatmalı LCD, kapsamlı tanılama raporlaması sağlar ve bu bilgileri aşağıdaki dillerden herhangi birinde görüntülemek için OBP aracılığıyla yapılandırılabilir:

İngilizce - Çince - Japonca - Almanca

Fransızca - Hollandaca - İspanyolca - Portekizce

İsveçce - Fince

Tüm sistemler doğrudan Toprak Modülüne bağlı olduğundan, metin ve tanılama simgeleri, makinenin herhangi bir bileşeninin arızalı olup olmadığını açıkça gösterir.

Tüm sistemler doğrudan Toprak Modülüne bağlı olduğundan, metin ve tanılama simgeleri, makinenin herhangi bir bileşeninin arızalı olup olmadığını açıkça gösterir.

Yerleşik eğim sensörü, canlı verileri doğrudan ekrana bildirebilir. Sensör, makinenin sevkiyatından önce üretim hattında bir düğmeye dokunarak zahmetsizce sıfırlanabilir.

Yerleşik eğim sensörü, canlı verileri doğrudan ekrana bildirebilir. Sensör, makinenin sevkiyatından önce üretim hattında bir düğmeye dokunarak zahmetsizce sıfırlanabilir.

Bir OBP ekranı, OEM'ler ve Servis Mühendisleri için makineye özel, programlanabilir parametreleri ayarlamak için basit, sezgisel bir kullanıcı arayüzü sağlar.

Bir OBP ekranı, OEM'ler ve Servis Mühendisleri için makineye özel, programlanabilir parametreleri ayarlamak için basit, sezgisel bir kullanıcı arayüzü sağlar.

Tüm sistemler doğrudan Toprak Modülüne bağlı olduğundan, metin ve tanılama simgeleri, makinenin herhangi bir bileşeninin arızalı olup olmadığını açıkça gösterir.

Tüm sistemler doğrudan Toprak Modülüne bağlı olduğundan, metin ve tanılama simgeleri, makinenin herhangi bir bileşeninin arızalı olup olmadığını açıkça gösterir. Yerleşik eğim sensörü, canlı verileri doğrudan ekrana bildirebilir. Sensör, makinenin sevkiyatından önce üretim hattında bir düğmeye dokunarak zahmetsizce sıfırlanabilir.

Yerleşik eğim sensörü, canlı verileri doğrudan ekrana bildirebilir. Sensör, makinenin sevkiyatından önce üretim hattında bir düğmeye dokunarak zahmetsizce sıfırlanabilir. Bir OBP ekranı, OEM'ler ve Servis Mühendisleri için makineye özel, programlanabilir parametreleri ayarlamak için basit, sezgisel bir kullanıcı arayüzü sağlar.

Bir OBP ekranı, OEM'ler ve Servis Mühendisleri için makineye özel, programlanabilir parametreleri ayarlamak için basit, sezgisel bir kullanıcı arayüzü sağlar.